Collaborative robots, or cobots, are redefining the landscape of manufacturing and logistics by working alongside humans to optimize production. As businesses strive for leaner, more efficient operations, maximizing cobot efficiency has become essential.

Here’s where remote monitoring steps in as a game-changing technology, empowering businesses to enhance cobot performance, extend uptime, and streamline maintenance.

The Role of Remote Monitoring in Cobot Operations

Remote monitoring enables real-time tracking of cobots, collecting and analyzing data on performance, workload, and system health. Through sensors, data processing, and cloud connectivity, remote monitoring tools provide operators and managers with insights into cobot operations, helping them make informed decisions that optimize performance.

In the context of Industry 4.0, remote monitoring complements IoT technologies to support a data-driven environment. These tools turn raw data into actionable intelligence, offering immediate visibility into cobot behavior across manufacturing lines or facilities.

This integration not only maximizes the potential of individual cobots but also enhances the efficiency of interconnected systems.

Key Benefits of Remote Monitoring for Cobot Efficiency

Remote monitoring brings a suite of advantages that support efficient, reliable cobot operations.

Enhanced Productivity and Reduced Downtime

One of the most significant benefits of remote monitoring is its ability to boost productivity. By enabling real-time monitoring, remote tools allow operators to proactively manage cobots, minimizing disruptions.

For example, data analytics can reveal performance irregularities, allowing managers to adjust cobot operations before they impact productivity. When issues are detected early, they can be addressed without major interruptions, reducing downtime.

Predictive Maintenance

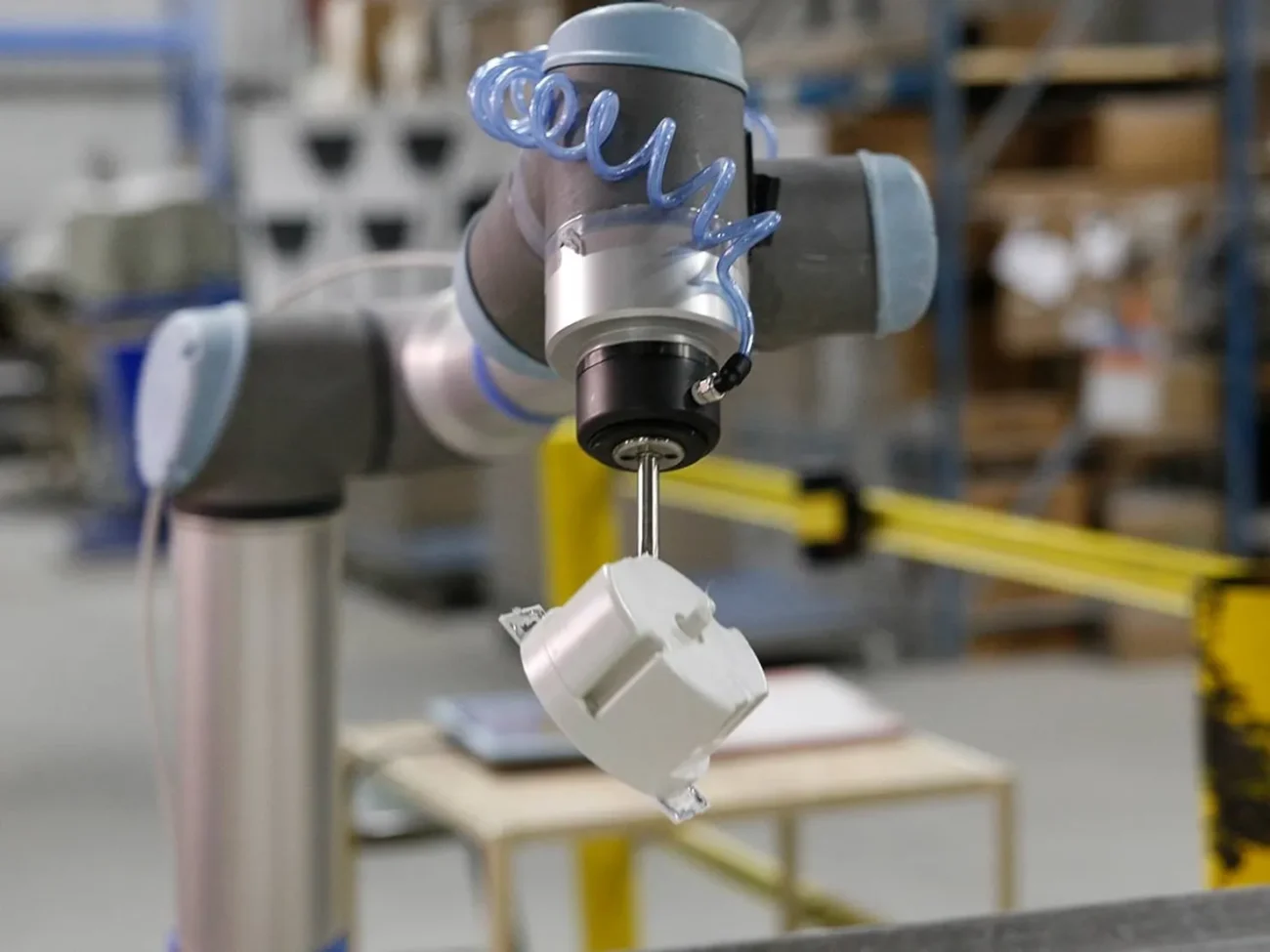

Remote monitoring tools are invaluable for predictive maintenance. By collecting data on cobot usage patterns, sensor readings, and component wear, these tools identify potential issues before they become problems.

For example, if a cobot is at risk of motor failure, a remote monitoring system can alert operators to replace or repair parts before an actual breakdown occurs. This proactive approach to maintenance helps reduce repair costs, prolong cobot lifespan, and keep operations running smoothly.

Energy and Resource Efficiency

Energy efficiency is another critical factor for businesses seeking to minimize costs. With remote monitoring, operators can track energy consumption for individual cobots, adjusting their usage to minimize waste. By making cobots more energy-efficient, businesses not only reduce costs but also contribute to sustainability goals.

Features of Effective Remote Monitoring Tools

A robust remote monitoring tool should include specific features to ensure seamless integration and effective cobot management.

Real-Time Data Collection and Analysis

Effective remote monitoring starts with continuous data collection, capturing information on speed, workload, energy use, and environmental conditions. Real-time analysis allows operators to detect deviations from normal performance and respond swiftly to potential issues, maximizing uptime and productivity.

Alerts and Notifications for Critical Events

Immediate alerts for critical events like overheating or connection failure are essential. These alerts can notify operators through mobile or desktop applications, enabling quick responses that reduce downtime.

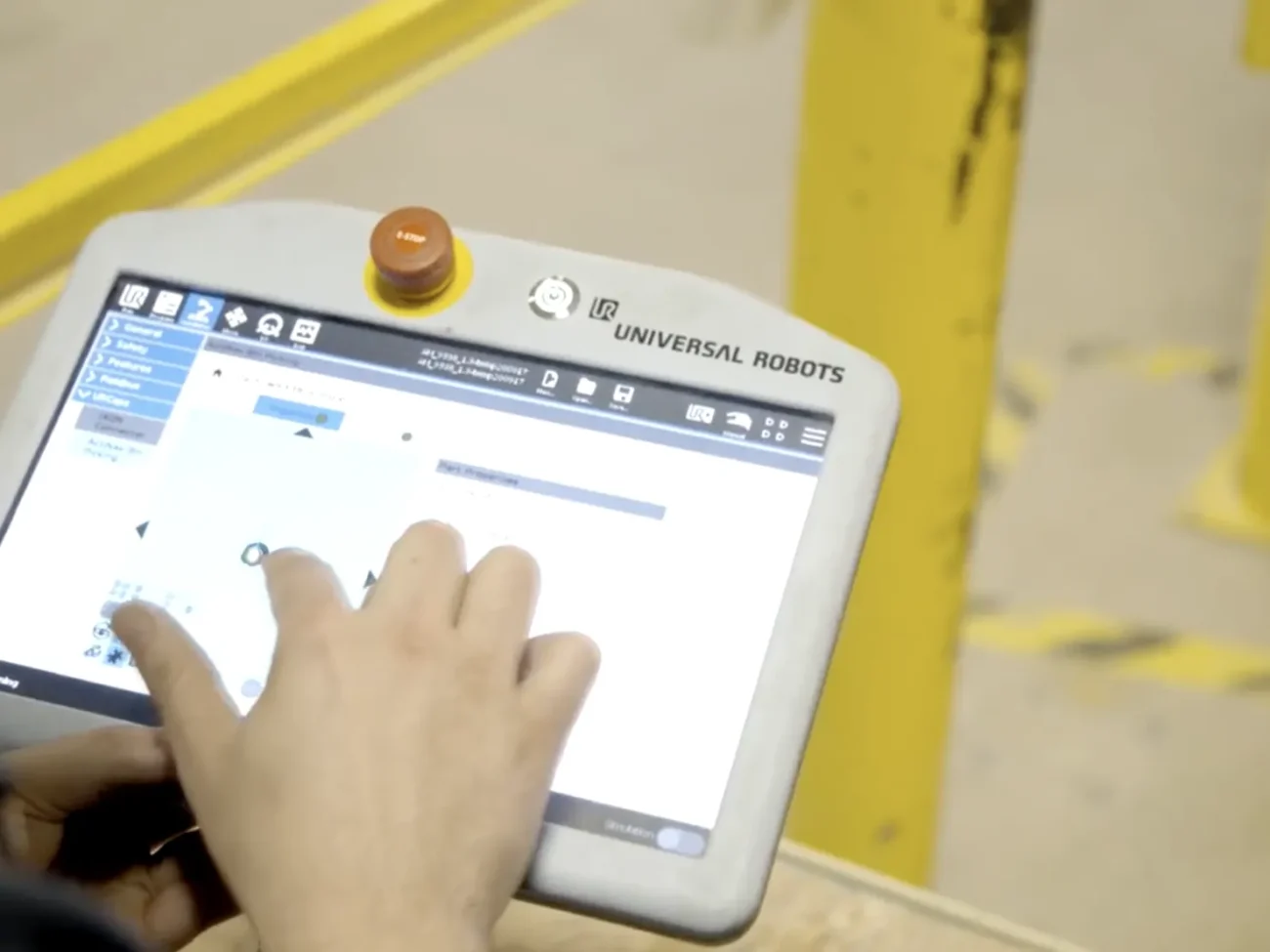

With features like Olis Connect from Olis Robotics, businesses can use a plug-and-play product designed for remote monitoring and error recovery of Universal Robots (UR) cobots, letting them run processes unattended with a recovery plan in place.

Dashboards and Visualizations

Dashboards that display performance metrics in a user-friendly format help operators and managers quickly interpret data. Graphs, charts, and other visualizations offer an at-a-glance view of cobot health and productivity, making it easier to spot trends and outliers that may indicate underlying issues.

Integration Capabilities

To ensure smooth operation, remote monitoring tools need compatibility with other industrial systems, such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software. These integrations allow data from cobots to flow seamlessly into broader data management systems, giving operators a holistic view of production.

Challenges and Considerations for Implementing Remote Monitoring

While the benefits of remote monitoring are clear, companies should consider potential challenges in implementation.

Data Security and Privacy Concerns

Remote monitoring involves data transfer and storage, often over the cloud, which raises data security concerns. Ensuring cybersecurity is vital to protecting proprietary information and operational data. Companies can mitigate these risks by using encryption, access control, and regular security audits.

Connectivity and Infrastructure

Reliable connectivity is crucial for effective remote monitoring, especially in large facilities or remote locations. Network infrastructure should be robust enough to handle high data volumes and maintain consistent communication with cobots. Backup systems are also advisable to prevent data loss during outages.

Costs and ROI Analysis

The upfront investment in remote monitoring tools may be significant, especially for small to mid-sized companies. However, businesses can perform a return-on-investment (ROI) analysis by calculating savings in downtime, maintenance, and productivity improvements. Many companies find that the cost savings and efficiency gains offset the initial expenses over time.

Operator Training and Adoption

Finally, training operators to use remote monitoring tools effectively is essential. By providing comprehensive training and support, companies can ensure that staff members are comfortable with the new technology and able to use it to its full potential. This investment in training ultimately contributes to maximizing cobot efficiency.

Conclusion

Remote monitoring is a powerful tool for enhancing cobot efficiency, offering benefits like increased productivity, predictive maintenance, and data-driven insights. By investing in the right tools, companies can make informed decisions that optimize workflows, minimize downtime, and reduce energy consumption.

As technology advances, remote monitoring will continue to be central to maximizing cobot potential, ensuring that businesses remain competitive and efficient.