There are many processes and approaches that exist in the world and are widely used that people do not know a lot about. Although they are not really that difficult or complicated to make use of and have benefited from, many still fail the basic knowledge about them. An example of this would be catalytic oxidation. It sounds rather sciency but at its core, it is not that troublesome to know a lot more about it. Catalytic oxidation is a procedure that oxidizes elements through the use of catalysts. Mutual uses include the oxidation of biological mixtures through natural oxygen. Such developments are piloted on extensive remediation of contaminants, manufacture of prized chemicals, and the construction of energy. In this article, we talk more about it.

Getting Familiar With It

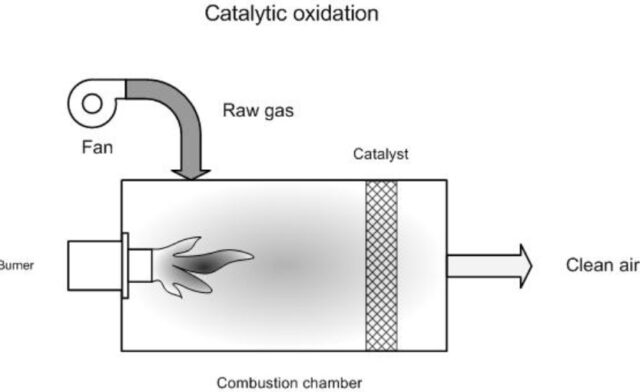

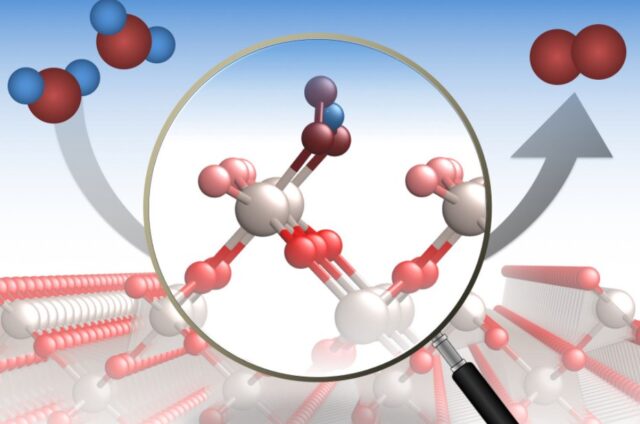

So who uses this procedure and why? Infragas.co.uk’s catalytic oxidation empowers the oven companies to form compact and dependable systems, which are easy to upkeep, are budget-friendly, have speedy actions, and are more environmentally sustainable. A chemical response known as gas oxidation is triggered via a substance whose physiognomies are not rehabilitated gradually. The response arises amongst the nourishing gas (flammable) that drifts internally within the oxygen and heater of the encircling environment (combustive manager): the interaction of these two components, over the catalytic pad, accordingly fore heated, produces gas oxidation through the release of thermal energy. The response is exothermic and cultivates warmth over infrared rays (IR). One of the best ways to know more about something is to evaluate its positive and negative sides. This is exactly what we do right here and now. Read on to find out more about the pros and cons of catalytic oxidation.

The Pros

Let us start things off by looking at the positive aspects of catalytic oxidation. The following is a list of its most important pros.

1. No Fuels Process

Superior quality vapor oxidation in complete deficiency of flame, as the catalyst initiates the oxidation of the flammable at an inferior heat than its detonation temperature. It is a harmless process with the resulting option of presentation in possibly volatile atmospheres (FM and ATEX specialized heaters are accessible).

2. Speedy Beginning

The Development & Research Department has calculated a catalytic heater through an extraordinary performance catalyst that starts quickly, shortens the fire heating stage which subsequently quickens the action period, with applicable energy saving.

Its infrared heaters crank up in 10 minutes, making it the shortest pre-heating point of all customary catalytic schemes existing globally, taking up the identical electric power tangled at the beginning. Shortening anything is important in the industry, so this pro is one of the more important ones.

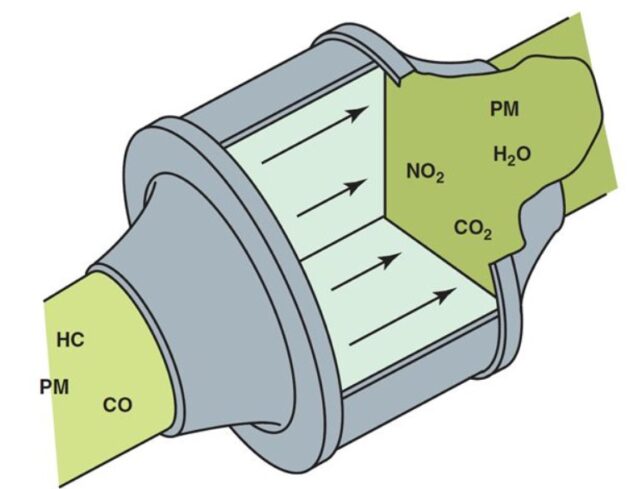

3. Lack Of HC, Nox, And CO

Catalytic gas oxidation produces entirely H2O (water vapor) and CO2 (carbon dioxide) deprived of the discharge of HC (unburnt hydrocarbons), NOx (nitrogen oxides), and CO (carbon monoxide). It makes the process environmentally safe and incomparably better to some other options still in use. It is important to be as green as possible right now, and this process truly does have a future in a world that is trying to be more environmentally conscious.

4. Controlling Temperature

The catalyst surface’s temperature can be controlled by a stand-in on the weight of the vapor: the infrared wave’s frequency is adaptable from average to extended exact actions. Having such a range is quite useful for obvious reasons.

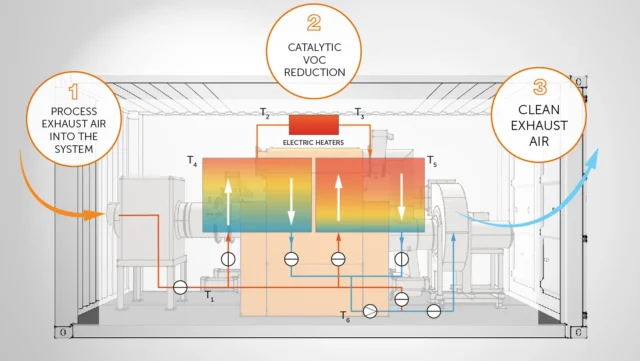

5. VOCs Abatement

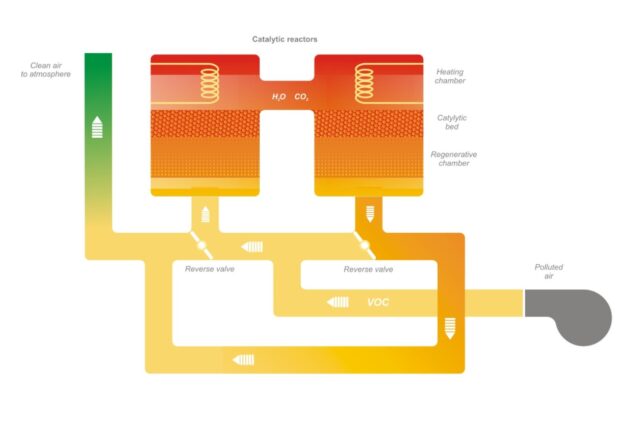

Through catalytic technology, the Volatile Organic Compounds (VOCs), the alcohols and the solvents, and numerous other contaminating chemical composites are disintegrated at molecular volume and renovated mainly in CO2 (carbon dioxide), and H2O (water vapor) instantly as they originate in interaction with the catalyst surface.

The Cons

Since we do not live in a perfect world, there are also the negatives that we need to deal with during the procedure of catalytic oxidation. Let us take a closer look at some of these cons.

6. The Cost

Manufacturing the expenses of catalytic oxidation preparation and modules is expensive. The lifetime is also not that great and fairly limited. Things that are better than others are usually more costly, and this type of negative is usually something that people are willingly taking on.

7. Difficult Modeling

Interpreting the biochemical response procedures and difficulty of the method can lead to additional challenging prediction and modeling. Similar to the cost, it is an aspect of the whole process that needs to be accepted.

8. Delicate To Variations

The system is delicate to variations in energy details in the gas. Catalytic oxidation is a process that cannot be dealt with lightly and developers need to be highly aware of their surroundings so that things do not get disrupted. It is why those handling it always need to know exactly what needs to be done, how, and when. Safety is always the number one concern.

9. Inferior Yield

Catalytic oxidation causes an inferior yield for VOC elimination when compared to another procedure, thermal oxidation. Although the yield is lower, it is still a very useful option to have as thermal oxidation is not always applicable nor does everyone want it.

10. Risk Of Dioxin Creation

There is always a risk of dioxin being created in the company of chlorinated mixtures and those using it have an extra thing to deal with. Dioxins are extremely lethal and can generate development and reproductive difficulties, along with hormonal issues, harm the immune system, etc. It is definitely one of the more concerning side effects and one of the more worrying negatives.

11. Subject To Poisonous Substances

To continue the topic of dangerous materials and substances, here is another con similar to the creation of Dioxin. Actually, every catalyst is capable of catalyst poisons and contaminating elements. It leads to problems in the later stages of manufacturing should it happen.

12. Burning Causes Dust

The process of burning usually creates certain substances no matter the process. You counter this and continue having a productive procedure, all of the dust must constantly be detached before burning. It is a tedious job that needs tending to but a rather necessary one.

13. Cannot Be Regenerated Once Deactivated

Basically, there is no going back. Once catalysts are deactivated, they are no longer able to be redeveloped and are disposed of.

Conclusion and Takeaways

To conclude, catalyst oxidation’s pros greatly outweigh the cons. Although there are more cons than pros, they are mitigated in the grand scheme of things. The process is here to stay and it is too good and beneficial not to be used. As with other things, there are certain dangerous aspects to catalytic oxidation but with care and skillful application, it is a great procedure overall.