Naturally aspirated gasoline engines, which used to demonstrate the prestige and high class of the car, are now being replaced by turbocharged motors. Even with a small volume, they allow drivers to develop high speed.

At the same time, US car owners still do not trust turbo engines. The skillful mechanics from Indy Auto Man compare turbocharged engines with atmospheric ones to help understand which ones are better. They also explain what a twin-charged motor is.

Why Is a Turbo Engine Better Than a Conventional One?

Modern turbo engines of cars have many advantages:

Low fuel consumption

If you take a look at the best SUVs for gas mileage, you will see that most models have turbocharged engines. Part of the energy of the exhaust gases of atmospheric engines comes out with the exhaust. In a modern turbocharged engine, the pressure and temperature of the exhaust gases are used to save energy and allow the car to reach high speeds.

Electronics fully control the filling of the cylinders with fuel. While the filling of atmospheric motors depends at large on the air temperature outside, crankshaft speed, atmospheric pressure, and other factors.

Good torque performance

The acceleration of a car with any gearbox depends on how quickly the engine can reach its highest power. The motor at low speeds must provide good torque. In modern turbo engines, boost pressure increases quickly enough. As a result, you can get excellent torque even at low speeds.

Since the increase in torque can cause a high load on the engine, the bypass valve activates and directs air flows around the turbine. It turns out a flat torque shelf. There is no such shelf in the aspirated motor, and the thrust depends on the engine speed. Atmospheric engines do not provide the same torque at low speeds – to obtain good dynamics, they must be high.

Less weight

Since turbo engines do not have a large volume, their mass is low. At the same time, they provide high power.

The Difference in Operation

The difference between these two motor options lies in the air intake technology. In a naturally aspirated power unit, the air flows to the spots with lower pressure. It penetrates the cylinders under a vacuum created on the intake stroke. The piston draws air.

Inflatable power units work according to a different scheme. A forced boost takes air into the cylinders. A kind of fan is installed at the inlet.

To increase its power, it must burn as much fuel as possible. A large volume of air can cause the combustion of fuel. One liter of fuel requires approximately one cubic meter of air. There are two ways to achieve this:

- Make the engine bigger. A few years ago, designers tried to use this scheme and increased the volume of cylinders and their number. The W12 and V16 engines were created this way, having a volume of 10 liters. But such a scheme turned out to be impractical since, in the end, the motor turned out to be very heavy;

- Increase the amount of fuel burned without expanding the volume of the power unit. This technology is more appropriate. It involves forced air in the cylinder.

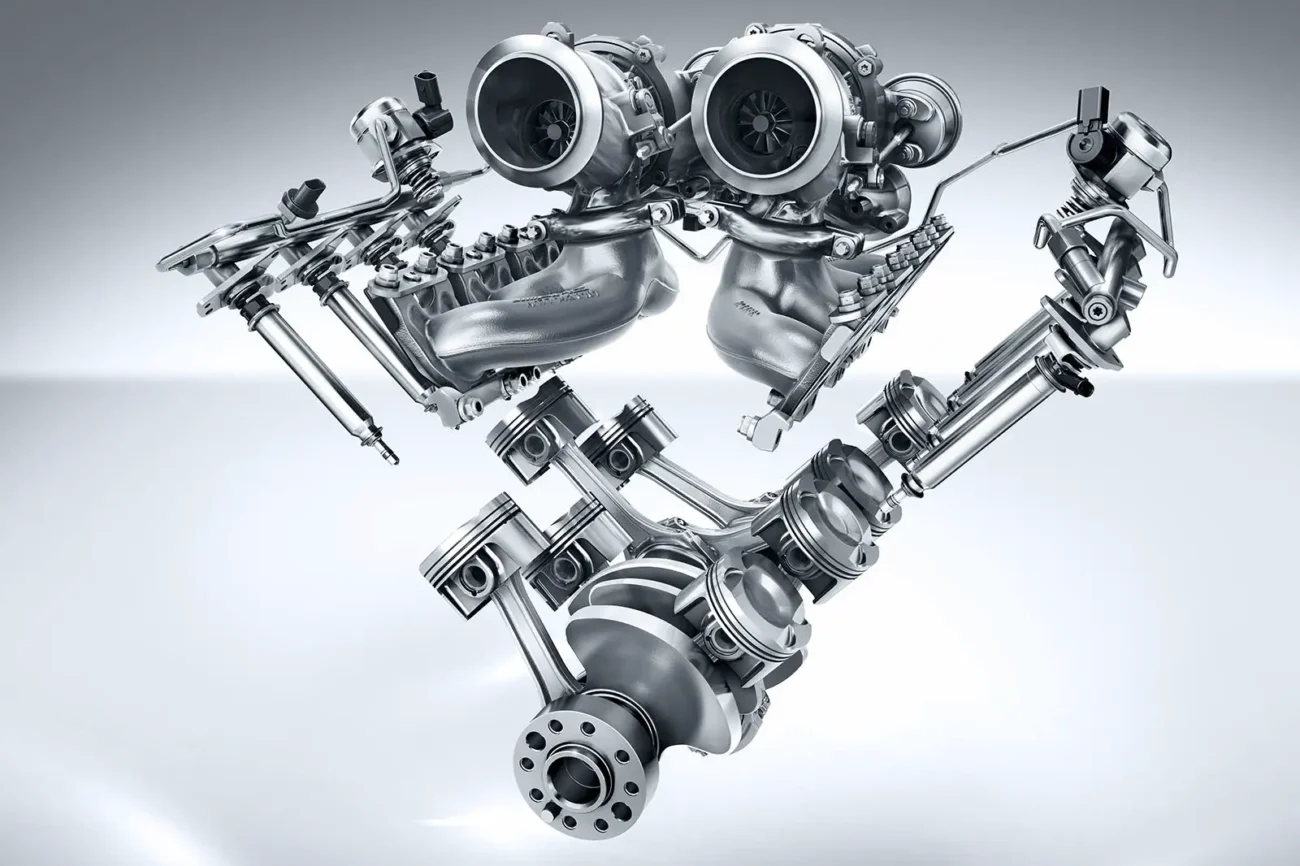

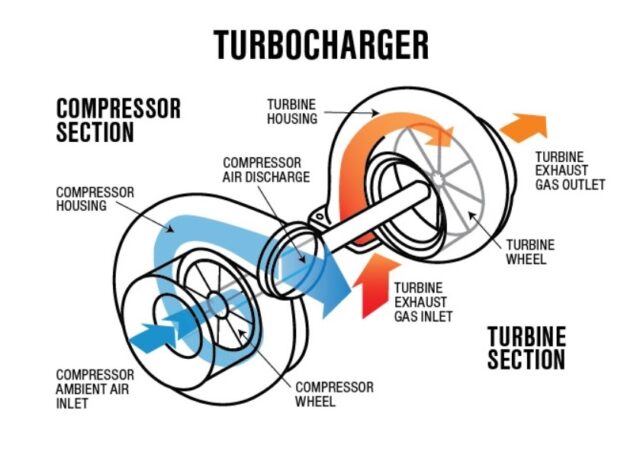

The principle of a turbocharger operation is as follows:

- Air is forced into the air filter and then into the turbocharger.

- It contracts and increases the volume of oxygen. When air masses are compressed, they are heated, and the air density reduces.

- From the turbocharger, the air goes to the intercooler, where it is cooled. After the temperature is restored, its density increases, reducing the risk of fuel assembly detonation.

- The air passes through the throttle into the intake manifold and then enters the cylinders of the power unit. There is much more oxygen in it than in the atmospheric power unit. A large volume of oxygen makes it possible to burn much fuel. As a result, engine power increases.

- After combustion, the fuel assembly enters the exhaust manifold, and the hot air flow enters the turbine.

The exhaust gases turn the turbine shaft when passing through the turbine, and the air compresses. The temperature of the exhaust gases becomes lower, and the pressure decreases as some energy is expended to keep the compressor running.

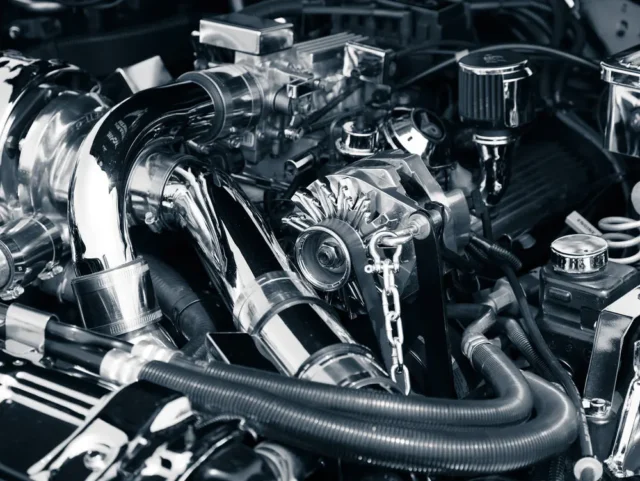

Depending on the type of engine and its configuration, the turbocharger can also include the following elements:

- A blow-off is a bypass valve that prevents the compressor from going into surge mode. If the throttle suddenly closes, the airflow in the system rapidly reduces. In this case, the turbine still rotates by inertia at the same speed, and the pressure drops behind the compressor. The Surge mode can damage the turbine support bearings. Blow-off determines the moment of the sudden closing of the damper and removes excess pressure into the atmosphere, protecting the turbocharger from damage;

- A wastegate is a mechanical valve that controls the pressure produced by the turbocharger. Many gasoline engines work with wastegate. The main task of this valve is to create a free exit of exhaust from the system, excluding passage through the turbine. This allows you to track the energy of gases and adjust the boost pressure.

What to Choose?

The experts can confidently say that the new turbo engines are significantly superior to atmospheric ones. And yet, most of the manufactured passenger cars are equipped with old aspirated ones due to several disadvantages of turbo engines:

- Small resource of turbines. As a rule, the turbine of a gasoline engine serves up to 100 thousand miles. Its repair is expensive;

- Engine operation in adverse conditions. Since the pressure and temperature in the turbine cylinders are higher, this accelerates the wear of the motor;

- Unstable traction. On older supercharged engines, the turbine took some time to get the impeller to rotate. But new technologies have solved this problem.

If you buy a new car, choose it with a turbocharged engine. It will be more economical and powerful. With careful operation, the motor will not fail for a long time. If you are purchasing a used car, consider the mileage and condition of the engine, and buy a vehicle only after a thorough technical check and test drive.